Final Thesis Link

Above is an issue link to the final copy of my DVR. This about sums up the entire project.

Cheers

Update… The end is so so so close….

I think im actually going to have half a day left stress free. As of 10 mins ago I completed my model images will be up soonish. I have also completed my renders and photos for presentation as well as my 2 presentation panels. All that is left to do is complete the DVR and learner testimonial. I’m confident i can have this done by the end of tomorrow. As I had quite a significant win on the stakes im of to enjoy the night stress free. Good luck all. Really keen for a few stubbies on wednesday arvo.

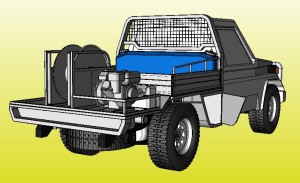

CAD

Finally my CAD is complete. I have been playing with different rendering programs and I have stuck with using photoworks. The renders aren’t as high quality as 360 but I can get results without it crashing. I dont have time to learn anything else. I will use 360 for my close up technical working shots. Heres a teaser of my first render that has semi worked it only took me about 3 days…. So slow.

Week 13 Update

So last week I sort of hit a wall in my progress development. This was largely due to trying to sort out my objet printing. I initially planned to have this organized as of Monday morning last week however deadline very quickly became Monday this week. This was due to the fact that my initial objet printing quote was rediculosly expensive and not within my project budget. Because of this i spent the entire week bouncing emails and CAD files back and forward with Andrew and various other companies to get the lowest quote.

I initial wished to get all intricate parts objet printed but after finding it to be expensive i then tried to reduce the number of parts and revert back to hand making some. However after receiving another quote it was still bloody expensive. So i then had to rework my CAD and quote for some parts powder and some objet…. Anyway this is what conculsion of i have come to. I will be getting the rear slip on unit, pump and bullbar objet printed and the tank will be powder printed. However the powder printed tank will no be used in my model I have made an MDF block tank that will be. This is due to time constraints and the effort required to finish powder. This was finalized yesterday so im hoping by the end of the week. Fingers cross Andrew doesn’t stuff it….

So with the making of my model pushed a long way back I intend to attack my DVR this week and begin my CAD renders. I anticipate the renders will take ages so i’m putting of doing it (THIS PROBABLY ISN”T WISE.. OH WELL). I hope to get a fair wack of this done this week. Then I can get back into my model when all my parts arrive. I still think im on track but white paper syndrome is getting the best of me with the DVR. Its been so long between writing stuff.

Update

So over the last week I have really been progressing on my model. This is my main focus at the moment basically because its the most time consuming and i don’t want it to be left to the last week. Ideally I will have it close to complete by the end of next week. I’m basically at the stage of finishing all the parts I needed to make myself I only now have my ob jet printing to worry about. This will be sent tomorrow afternoon hopefully for a quick turn around time.

My Cad is mostly done as I needed it for the making of the model however small working parts of importance which cannot be show in the model are yet to be CAD’d. This will be my next aim so I can start producing some high quality renders of the missing model components.

My DVR still hasn’t been started but this is really about to happen right NOW. I can’t put it off any longer. This will be the main focus in between finishing parts and waiting for 3d prints.

Bellow are progress shots of my model an a shot om my CAD work to date.

CAD CAD CAD Bloody CAD

Over the last week I have pretty much been doing the same as what I have been doing for the last 2 weeks, CAD. I’m so ridiculously over it. The model is really coming along well however I didn’t anticipate there would be so much work. I have been CAD’ing every component well and accurately it just turns out I have literally hundreds of parts. I really hope to have this done by the end of the week as I will be heading back to my dad’s shed next week to complete the scale model. Everything is falling into place. With the last of my car body being CNC milled. I will also complete this week so that the model can be completed. If all goes well I should have a fully constructed model by next week. Then I just have to send the appropriate components off to be objet printed. All is on track it is just so much bloody work…. Below is a CAD pic of where I’m at.

CAD Update

Over the last week I have still been fleshing out my design in CAD. It has been slow progress at the moment mainly due to the construction of the tray under. The bellow images depict where I’m currently at. All the components are to scale and the brace sizing etc is all designed using available steal sizes and thickness. The tray bracing system is modelled on the current DSE

Steel Sizes

For my project it is crucial that I know the industry steel standard sizes. I simply just googled this and found a couple of links showing what steel is available and a what size. The bellow links show both sheet and long section steal. These size will be important for the CAD model.

Rotomoulding Soild Sections into a Design

Bellow is a great link explaining a plastic composition and a method to making solid parts directly into the rotomoulding process. This process may be handy for screw lugs etc…. Great Link.

November 12, 2009

November 12, 2009